|

|

18 December, 2001

Jordan Dickens at the "Feeder Switchboard" is the supervisor for the power and water plants at the McMurdo Research Station (Although, this tour took place on December 12th, I will write this journal on Dec.18th…It deserves a day of its own.) Jordan Dickens is employed by Raytheon Polar Services as the Supervisor for the "Power Plant" and the "Water Treatment" plant at the McMurdo Research Station. He first came to Antarctica in 1986 with a vast amount of experience working with engines in the U.S., as well as in the oil fields of South America and Morocco. Not only has Jordan Dickens visited 68 countries and seven continents, but he has also been fortunate to work at all three U.S. research stations in Antarctica. He was the operation manager for one year at the Palmer Research Station on the peninsula. He worked two years at the South Pole as the power plant mechanic and station electrician. He has wintered six times and summered eight times on the "ice". This year he is here from October to February. His love for engines was apparent as he led Dr. Sergei Korsun and me on a tour of the power plant. I felt safe in knowing that he understood the importance of his role in providing the "lifeblood" for daily survival in this extreme cold weather environment. The "town" of McMurdo could not exist without relying on power to keep pipes from freezing and electricity for heating, cooking, and powering equipment. If the engines stopped, McMurdo would not have the electrical power to sustain livable conditions on this icy continent.

I couldn't help but feel the power generated from the six engines (900 kilowatt/ 1200 horsepower each) as soon as I stepped into the engine room. I could feel the vibrations, and still hear the humming of the engines, despite the protective earphones. The engines burn about 25, 000 gallons of diesel fuel a week. This is equivalent to 3600 gallons or 75 barrels a day (15,000 Liters a day). The engines are overhauled every 20,000 hours and parts are replaced as needed. The #1 engine has been running since 1980. To date, it has logged 94,002 hours (if a car drove 45mph for 94,002 hours; it would have traveled about 4.3 million miles). Quite an impressive feat for an engine that helps power a huge complex in such a harsh environment! The power plant provides electrical power for all dorm buildings, the Crary Lab, and the work facilities at McMurdo. The Vehicle Maintenance Facility, which maintains and repairs heavy-duty equipment uses the most watts to maintain equipment such as cranes, air compressors, and lights. The Galley, which houses the kitchen/dining area, has large ovens, which draw from the power. Although there are six engines, normally only three run at a time. The other three engines are maintained as backup systems in case one engine fails. (McMurdo Research Station, one of the largest research stations in Antarctica, can house around 1200 people. It takes three engines to provide the power to run this town.) If an engine should fail, it is disconnected in order to get another engine on line.

The engines at the power plant are quite impressive!

The red box houses the main switch. Feeder "A" is a pilot switch, which would be the first to go down. Feeder "F", which generates the electricity for power and water, is the last to go because these two are essential. In a big storm, if ice builds up in radiators, all six engines may need to be put on-line. Normally radiators get rid of excess heat, but here in Antarctica instead of liquid to air, it is liquid to liquid (antifreeze). The excess heat is captured from the radiator and sent to the water plant to heat seawater. It can also be sent to the Crary Lab and to the dorms. Eventually, they hope to capture heat off the exhaust. This, along with the antifreeze, could possibly save three-fourth million gallons of diesel fuel a year.

Spike and I are examining a piston from a 16 cylinder engine. (There are 16 pistons in each engine.) When a valve overheated, it caused the valve head to come off. This got embedded and destroyed this piston.

Computers factor into much of everything we do in "today's world". On my tour of the power plant, I could see first-hand how computer technology is effectively integrated into the working environment on the remote continent of Antarctica. The McMurdo Research Station, because it is in such a remote land, must be self-reliant and self-sustaining in order to survive such harsh conditions. At the power plant, a temperature control system, which connects the computer to all the buildings in the McMurdo complex, can control the building temperatures from this site at the power plant. Bob Murway, who works for a private contractor, which designs and sells parts interfaced to this system, represents this manufacturer from Denver. It is his first time in Antarctica. He came to Antarctica to make a technical evaluation in order to set up a transition. This company, which uses software from Alerton Technology, is working to control this site from Denver, Colorado. By having the computer connected to all the buildings, the computer can show the amount of heat taken, how much heat can be accepted, or to turn on the fans when needed. The computer can also change temperatures in buildings, such as the galley or dorms, without physically going out into the cold to do so. This makes it more efficient and accurate than being there. If a pump goes off, or something fails, then a message will pop up on the computer screen to alarm or notify when adjustments or repairs need to be made. If a temperature is too high or too low in a building, then it can be adjusted from this computer site. It will also alarm them when the steam boiler in the kitchen needs to be modified.

Jordan Dickens taught me a lot about Antarctica during my tour of the power plant. The photo above shows the icebreaker docked at the ice pier. He explained how the ice pier was built. Since there was no other way to build a pier for the ships, someone came up with an ingenious solution to make a pier from ice in order to moor (tie up) the ships when they came into the harbor. I could see the ice pier from the power plant. Jordan said that ice pier must be made every four or five years. He said that first holes must be drilled into the ice, so that pumps can be lowered. Then seawater is pumped on top of the ice. A berm (a mound or bank of snow) is built then flooded with this salt water. It freezes, then cables are crisscrossed over the ice and sediment added on top. The ice pier is strong enough to support vehicles driving over it, as well as icebreakers and freighters moored along side it.

As the icebreakers and the "Tanker" come into McMurdo, volunteers are solicited to be "linehandlers" to drag around heavy nylon and cable mooring lines to help dock these vessels. Jordan Dickens sent me a photo of the "Tanker", which is named the Gus.W. Darnell. It is docked alongside the ice pier. It will re-fuel the icebreakers at sea (at the ice edge) before heading up the broken-out channel to the station to off-load about seven million gallons of fuel. This fuel includes regular gasoline, AN-8 for aircraft and helicopters, and JP-5 fuel for heavy equipment and the power plant.

Jordan Dickens also sent me a photo of the freighter, the "Green Wave", approaching the ice pier. This vessel was bringing in supplies, vehicles, bedding, food, building supplies, and equipment that had been ordered a year or two in advance. The red "milvans", or box-like containers on the deck, are used as storage containers for cargo. The freighter will also have building material that will be transported to the South Pole for the new station construction. These supply vessels only come once a year, usually around the third week in January. It will take about a week to off-load, then "milvans" packed with retrograde and waste products will be loaded onto the freighter to be taken back to the States.

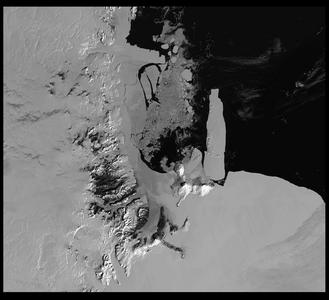

Before I ended my tour of the power plant, Jordan Dickens also told me more about the B-15 iceberg, which is about the size of the state of Delaware. It broke off the Ross Ice Shelf a couple of years ago, and it is now blocking part of the harbor leading into McMurdo Sound. This massive iceberg is affecting the current ice from leaving the harbor. If it continues to block the harbor, it could possibly affect the weather, marine animals, and the ice edge for several years. The iceberg is blocking currents that normally carry sea ice out of the harbor. This satellite image gives a better description and understanding as to the relative size of this massive iceberg.

Contact the TEA in the field at

.

If you cannot connect through your browser, copy the

TEA's e-mail address in the "To:" line of

your favorite e-mail package.

|