|

|

28 November, 2001

After brainstorming all night, we decided that repairing the fractured bottom tank cover would be in vein. The material it is made from is just not suitable for the frigid temperatures found at the South Pole. Even if we did repair it, it would just develop more fractures as it was placed over the tank. Instead, we decided to cut the cover up so that it would fit inside one of the many recycling bins found around the station.

The strategy we decided to go with relies upon the integrity of the top cover. The top cover is made of a different material and it is also thinner. We hope these differences will allow it to remain flexible outside. The cover is large enough to completely encase the lid and upper half of the tank. As compensation for the loss of the bottom cover, we are going to wrap the gap between the tank and lid with a few layers of felt. Hopefully, this strategy will do the trick in creating a perfectly light tight tank. To determine this, a light test has to be conducted.

Conducting a light test is straightforward. Attached to the lid of the tank will be two electronic eyes, called optical modules (OMs). Optical modules are designed to detect light, even the smallest amount of light called a photon. Inside an optical module is a device called a photomultiplier tube (PMT). A very high current is sent to the PMT, causing a large amount of electrons to collect on the many levels that make up the instrument. When light enters the PMT, striking the uppermost level, it causes some electrons to fall down and strike the electrons resting on the level below. The electrons which were just hit, fall to the level below them, and something like an avalanch has begun. The number of electrons falling continues to multiply until the last level of the PMT is reached. An analogy to this would be a room filled with mouse traps. If something triggers one of the traps to go off, a chain reaction will begin. In the end, large numbers of mouse traps wo!

uld be triggered, evident by all of the noise created. The noise created in the PMT is an abundance of electrons which are then transfered to an instrument as a pulse. If a pulse shows up on our instruments, it is informing us that light was detected and our tank is not light proof. We would then have to determine the source of the leak. Our work cannot continue until we have determined that our tank is 100% light tight.

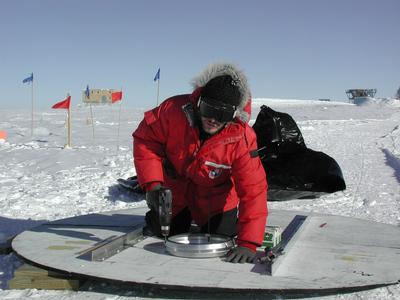

Today we constructed the lid out of plywood. It was painted black on one side and white on the other. This is to help with the refection and absorption of heat and light. From the lid, we will hang two optical modules, which we still have to unpack, prepare, and calibrate. As long as the weather holds out, we expect to have the tank ready for the light test within 24 hours.

Biological Data

Saturated Oxygen: 88%

Pulse Rate: 85

Weather Data

Temperature: -30.5

Windchill: -63.3

Drilling holes in the lid for the OM's

Preparing the Optical Modules (OMs)for the detector.

Contact the TEA in the field at

.

If you cannot connect through your browser, copy the

TEA's e-mail address in the "To:" line of

your favorite e-mail package.

|