16 December, 2000

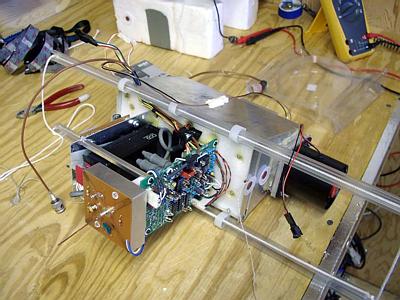

Today was spent getting the HYVIS ready for flight. Here you can see the "guts" of the instrument. This instrument has two CCD video cameras, one for high resolution and one for normal resolution, a leader film package, and a radio transmitter that actually sends back the video images in real time our trailer at SPARCLE central. The HYVIS is considered by the manufacture to be "disposable" but at $5000.00 each we are not going to dispose of them. That is why we use a tethered Blimp as opposed to the free release balloons that the weather service uses.

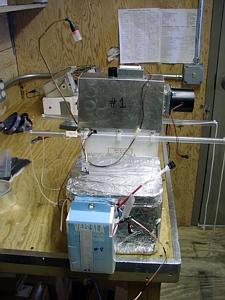

Driving all the electronics in the HYVIS, the light for the cameras, and the motors for the air intake and the leader film takes a large amount of electricity. Here you can see the battery pack for the HYVIS and the Vaisala RS80 Radiosonde. This instrumentation uses a variety of batteries that have been modified to produce the necessary voltage needed to run the whole package. Here you can see 5 "C" batteries in series and 20 "3 volt" lithium camera batteries in an arrangement that I am not sure about at the present. The blue box to the left of the battery box is the Radiosonde. We use the Vaisala Radiosonde because it give much more reliable humidity data that the "AIR" brand Radiosonde that is typically used here at the Pole. The FPH is the most reliable humidity sensor, and we would naturally like to fly it with the HYVIS. Unfortunately we are limited on lifting capacity of the Blimp to no more than 15 pounds. The HYVIS and the FPH both weigh about 15 pounds each so we can't fly them together. Maybe in the future we will have a bigger Blimp so we can fly both instruments together.

The finished package ready to go outside for a ground test. We ran the ground test for a couple of hours, occasionally throwing a hand full of snow at the intake fan in order to see if the suction would actually pull enough air into the camera chamber. We are hopeful that we will have the HYVIS ready to fly by Monday. We still haven't worked out the support harness yet. It is amazing how long it takes to do things here at the Pole. Every job seems to take three times as long as it would under normal "temperate" conditions.

Entering into the main tunnel, you can see the telescoping discharge pipe and the very rectangular shape of the machine cutter. It is somewhat a strange feeling walking into a tunnel under the snow. I inquired about stability and John said that these walls were far more stable than many of the "hard rock" mine tunnels he had worked in.

Contact the TEA in the field at

.

If you cannot connect through your browser, copy the

TEA's e-mail address in the "To:" line of

your favorite e-mail package.

|