14 June, 2000

14 June 2000

Mooring - The Final Chapter

At the end of the journal entry on 12 June, I left you with the question of

how the anchor-first, in-ice mooring deployment might differ from the

anchor-last, open-water deployment done that day. What follows is a

description of those differences. How many did you come up with?

There are basically two components to the differences. One is the way the

mooring is deployed and the other is the challenge posed by working in ice.

Let’s deal with the deployment first. In an anchor-first mooring, the

anchor is the first part over the side, just as the name implies. By

sending the anchor over first, the ship can stay in the same spot the whole

time directly above the target location. The difficulty this adds is that

there is more tension on the line from the start due to the weight of the

anchor pulling on the line as the equipment is gradually added to it.

Equipment is attached in stages just like in the anchor-last deployment, but

this time with the pieces you want nearest the bottom first, and the pieces

you want nearest the top last.

The challenge posed by working in ice is that you need a clear space to let

the mooring down through into the sea. This is accomplished by breaking

through the ice and then using the ships propellers to form a “pond” of open

water behind the ship. Once the pond is formed, the mooring assembly can be

lowered and released when the last piece, the top floats have been attached.

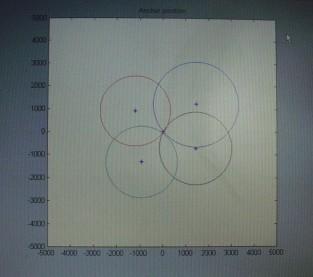

The challenge of ice does not end with the release. The recovery presents

another set of challenges. Just like with the previous mooring, John and

Jeff use signals between the transponder (near the anchor of the mooring)

and a hydrophone (lowered over the side) to determine the distance from the

ship to the mooring’s anchor. This is done from four separate points and

then distance circles are plotted from each point to find where they

intersect (see photos). The intersection is the location of the transponder

and therefore, the mooring’s anchor. The challenge here is that the ship

has to break through ice to get to each of the four points, and make enough

clear space in the ice at each point to lower the hydrophone down so it can

communicate with the transponder.

Once the anchor’s location has been determined, the ship must create a much

bigger “pond” in the ice so that once released, the mooring will make it to

the surface rather than come up under the ice itself. This large pond is

created by steering the ship back and forth along a series of lines, which

are over the mooring’s location. The ship’s movement churns the ice into

slush. Once the pond is created, the hydrophone is lowered over the side

again and a signal is sent telling the transponder to let go of the anchor.

Once released, the entire mooring assembly floats to the surface, hopefully

in the middle of the pond. On this trial, it was close to the middle, but

right next to a small ice floe.

Once at the surface, the mooring is hooked back to a line from the ship in a

different way than was done in open water. In this test, BM2 Ben Hicks

climbed into a basket, which was lifted by a crane over the top floats. He

then secured a line to the floats so they could be hauled back on board.

Again, the mooring is disassembled as it is brought on board. With the

anchor-first mooring recovered, disassembled, and put back in storage, the

mooring test phase of this Leg 3 of USCGC Healy is successfully completed.

Next up, testing maximum horsepower of the HEALY’s engines. Any guesses how

powerful they are? Look up the HEALY’s website,

http://www.uscg.mil/pacarea/healy, and see if you can find out how much

power this ship can generate.

Jeff attaches the hydrophone to the acoustic command unit.

This crane, made by Allied Marine Crane near where I live, will lift the cage to catch the floats.

John Kemp and Jeff Lord of Wood's Hole wait for the pond to finish forming.

Jeff lowers the hydrophone into the water.

John enters the data from the acoustic command unit to verify the mooring's location.

The HEALY reverses with BM2 Hicks in hot pursuit of drifting floats.

Success! BM2 Hicks attaches the hook to the float cage to the applause of those on deck.

The computer screen shows distance diameters and their intersection.

John begins transponding, sending signals to the transponder from the hydrophone using this acoustic command unit.

BM2 Ben Hicks gets lifted over the icy waters to go and catch a mooring.

A closer look at the intersection point shows the predicted location of the mooring anchor.

The "big pond" created by the HEALY.

Contact the TEA in the field at

.

If you cannot connect through your browser, copy the

TEA's e-mail address in the "To:" line of

your favorite e-mail package.

|