19 June, 2000

Coring Equipment and How it all Works

As we head towards ice on this Monday, I have been researching the

equipment needed to take core samples. Hopefully in the next day or two, we

will be testing the coring equipment in ice conditions. We will attempt to

extract a 30-meter core sample. It's time for mud, and lots of it!

The coring mechanism is made up of many parts, both big and small. As you

read through the descriptions, take a look at the pictures and illustrations

to help you form an image of just what a coring assembly looks like and how

it operates.

Core Cutter

This is the lowest part of the core assembly. It has sharp edges which cut

and shape the sediment entering the core liner as the corer goes into the

sediment.

Core Catcher

This piece rests on the upper edge of the core cutter. Curved finger-like

projections extend down to the lowest part of the core liner. The core

catcher helps keep the sediment in the core liner when the coring system is

being brought back to the ship.

Core Liner

The core liner is composed of 4'" PVC pipe. PVC pipe is recommended because

is readily available, stronger that other liners, and can easily be split

lengthwise in the field. The core liner fits inside the metal core barrels

and is where the sediment will be contained.

Core Barrels

The core barrels are 10 foot metal tubing that weight approximately 165

pounds each. The barrels are connected together by couplings that slide over

the tubing and are held in place with screws.

Piston

This is attached to the lowest part of the core barrel assembly. It passes

through the entire length of the core as the whole mechanism goes into the

sediment. In other words, it stays on the surface of the ocean floor as the

coring barrels and coring liner passes into the sediment.

Piston Stop

This four-inch piece of equipment prevents the piston from traveling through

the center of the center tube of the corehead.

Corehead

For a 30-meter core, a 5000-pound head is recommended.

For a 15-20 meter core, a 4000-pound head is recommended.

Trigger Arm

The trigger arm holds the corehead in place. When the trigger arm "opens"

the piston core is dropped at a freefall.

Gravity Corer

Activates the trigger arm.

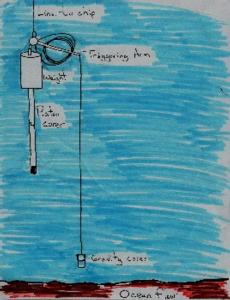

Illustration 1

The piston corer is lowered from the side of the ship by a 5/16" wire. Below

the piston corer is a small gravity corer.

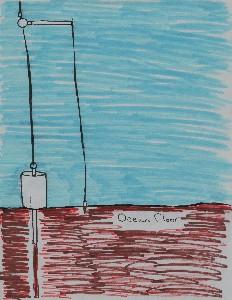

Illustration 2

As the gravity corer touches the ocean floor, the triggering arm is

activated. This sends the piston corer falling in a freefall to the ocean

floor.

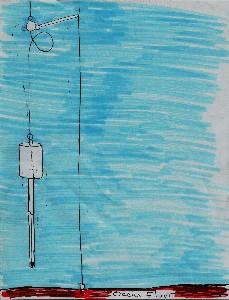

Illustration 3

When the piston corer goes into the sediment, the piston inside stops at the

surface. The piston corer continues down. The piston inside creates a

pressure difference between the top and the bottom of the piston corer.

This allows the sediment to enter the core liner without any deformation.

Illustraion 1 Labels from top to bottom: line to ship, triggering arm, corehead, piston corer, gravity corer, and ocean floor.

Aft Corehead. (4)

Core liners (white PVC pipe) and tubing (metal tubes), unassembled. (2)

Illustration 3 The triggering arm has been activated, sending the corehead downward, causing the piston corer into the sediment.

Illustration 2 This illustrates the gravity corer hitting the ocean floor, which will activate the triggering arm.

Corehead on the starboard side. (5)

The core cutter is the large piece of metal in the middle of the picture The core catcher is the silver object on the right.

Contact the TEA in the field at

.

If you cannot connect through your browser, copy the

TEA's e-mail address in the "To:" line of

your favorite e-mail package.

|