13 December, 2001

Richard "Chico" Perales gave me a tour of the Facilities Engineering Maintenance Construction Building, or "Building 136". Chico has been in Antarctica nine times, worked at all three of the U.S. stations in Antarctica, and wintered four times (See journal entry: December 20th). He said that 80 to 100 people work for this department in supporting science in Antarctica. In Antarctica, extreme temperatures and wind cause things to stress, so if something breaks down, the appropriate group (i.e. plumber, electrician, welder) will be given the work order to complete the designated job. Basically, if something breaks down, this group will fix it. The utility shop will fix motors, pumps, generators, doorknobs, air conditioning, heat, and fix broken tools. In the summer, new parts may come in on the next plane, but in winter they must work with what they have. No one says, "I can't" or "I don't have a part". They see a problem, then they learn to improvise and find a way to work around it. Chico says that it increases thinking skills because they must brainstorm to find other solutions to problems.

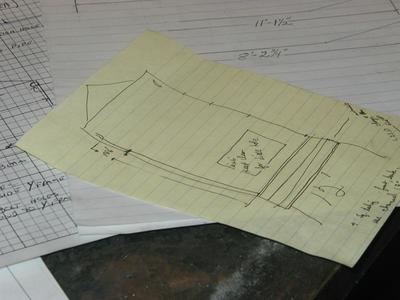

Math is used to figure out the best angles needed to bend or cut metal and pipes to fit specific needs. The measurements must be accurate, so measuring skills are needed with this job.

Scientists give drawings on napkins or scraps of paper with two or three dimensions. The people in this building will make it a reality by figuring out the structural details, such as what materials are needed and the best place for braces and reinforcements to withstand the extreme conditions. They build many things to support science research in Antarctica such as sleds, snow melters, box cores, and fish baskets.

This special cutter will bend and cut metal. Stainless steel is the metal of choice for scientists, but it is the hardest metal to work. The steel will be cut or bent to make angles.

They even make or repair pots for the galley (kitchen).

Chico introduced me to Dave Ackley, the material senior supplies person. He is in the Christmas spirit, and he definitely makes others smile. I came into this building expecting to spend 30 minutes, but I spent one of the most interesting two hours. What a great group of people working together to support science by making things work.

Olivia is working in materials to support the welders, metal workers, and plumbers here in McMurdo. Olivia's background is physical science, and she worked with an archeologist/field biologist in Texas before coming to Antarctica. She is from Alaska, and her strong point is organization. Her job entails keeping track of the materials and supplies in this area. She uses the computer, set up much like a system in the library, to catalogue and track supplies.

The shelves are organized in rows with identifying numbers and letters that will be matched to the supplies on the shelves, as well as tracked on the computer.

Metal tends to crack, so some parts are made of brass because brass doesn't stick to skin, and it can stand the coldness in Antarctica. It depends on the purpose; some may be used for one thing, but not for another.

The numbered red milvans are outside the building to store supplies and equipment. A forklift will bring the supplies into the building. The freighter will bring in supplies and equipment once a year. Anything to be retrograded back to the states will be put in the empty milvans to be reloaded onto the ship (See journal entry: December 18th for more information on the freighter).

Lumber and pipes are stored outside for use in McMurdo, or sent to the South Pole for the construction of the new South Pole Station.

In the winter, when it is dark 6 months out of the year, the red lights make it easier to find supply lines and know that this power is working. It is so cold in winter, lines get frozen.

Due to the extreme cold conditions, the pipes require 5 inches of insulation with tape run around the pipes. Six watts of voltage run through it to keep the pipes warm, then insulation is added on top.

(Close up of an insulated pipe)

Contact the TEA in the field at

.

If you cannot connect through your browser, copy the

TEA's e-mail address in the "To:" line of

your favorite e-mail package.

|