21 June, 2000

Jumbo Piston Coring System

Today is Summer Solstice, the longest day of the year. Of course above

the Arctic Circle, every day this time of year seems the longest day of the

year. Beginning tomorrow the long and slow slide to the arctic darkness of

winter begins; minutes of daylight start to slip away.

The Jumbo Coring Piston System (JCPS) coring procedure I outlined briefly

a couple of days ago, now can be illustrated more fully with the aid of

photographs I took during a test of the system. Hopefully, this will clarify

your understanding of how these long core samples are taken from the ocean

floor.

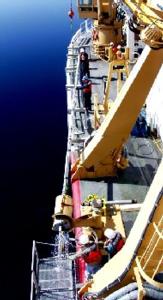

Picture 17 The corehead is then hoisted by a winch and lowered down into the water. For a review of how the JPCS works under water as it approaches the ocean floor, refer back to my journal entry for 06/19/00. Tomorrow, I will be covering the recovery method of the JPCS, as well as how the core samples are extruded from the core barrels and then sectioned for transport to a science lab.

Picture 16 The gravity corer is being lowered overboard.

Picture 1

Picture 4

Picture 8

Picture 5 In pictures 4 and five, the trawl wire is feed through the corehead and core barrels. On the "bottom" end of the JPCS main corer, the piston will be attached and inserted a few inches into the main corer, just above the core cutter.

Picture 6 Here, the piston has been attached to the trawl line and is being inserted into the bottom end of the main corer. The piston should pass through the entire main corer, and stop even with the surface of the ocean floor. The pressure differential at the top of the sediment column, caused by the piston allows the sediment to enter the main corer without any deformation to the column of sediment.

Picture 15 In picture fourteen and fifteen, the main corer is being lifted at the lifting collar. Then, it is slowly lowered overboard. The Core Handling Davit holds the corer in place. A winch is then used to lower the gravity corer overboard.

Picture 7 The core catcher shown here is then inserted into the main core. The curved "Chinese fingers" are inserted first. This mechanism works like the toy Chinese finger cuffs we all have played with at one time or another. It acts like a one-way valve. A more scientific example would be the valves in your heart. They allow blood to enter a chamber of the heart while traveling in one direction, and then prevents it from traveling back in the opposite direction. The curved fingers open and allow sediment to flow through it, and then it closes which holds the sediment in the main corer in place.

Picture 14

Picture 11 Shown in pictures ten and eleven, the trigger arm is then placed on the corehead. The trigger arm works much like a seesaw. The overall balance of the triggering system is based the leverage point (fulcrum) and the distance between the weights on either side (lever arm lengths). The 4,000-pound corehead is located only a few inches from the leverage point (fulcrum) while the 400-pound gravity corer is hooked to the device 48inches from the leverage point (fulcrum). This balance keep the trigger arm locked onto the corehead. When the gravity corer hits the ocean floor, the weight on the mechanism changes. This disrupts the balance, which causes the corehead to be detached from the triggering arm. The corehead then goes into a freefall to the ocean floor.

Picture 13 Before the JPCS is set overboard, a water hose is placed inside the main corer. The water fills up the main corer, lessening the hydrostatic pressure that will occur when the main corer falls through the water column. In plain English, if you please. If you placed the main corer in the water with only air above piston, as soon as the corer is going down through the water, the water from below would push the piston up through the corer. With water in the corer before hand, it acts as a force that pushes down on the piston as water from below pushes up. This balance of forces helps keep the piston in place.

Picture 2 In picture one and two, a "hero deck" is being secured over the starboard side of the Healy to aid in the procedure for deploying the coring mechanism. Safety is the biggest concern when working in the arctic, especially when working over water that has a temperature anywhere between 31 and 33 degrees Fahrenheit.

Picture 10

Picture 9 The core cutter shown in picture 8 cuts and shapes the sediment entering the main core with its sharp edge. The core cutter is being place onto the end of the main core in picture 9.

Picture 3 The 4,000-pound corehead, seen on the opposite end, was fitted with the ten-foot long metal core barrels. A total of four core barrels were joined to one another using couplings that fit over and around the core barrels. Then inside the core barrels, the core liner is placed. Together the barrels and liners make up the main corer.

Picture 12 The lifting collar is typically place 10 feet above the mid-point of the main corer. The purpose of the lifting collar is to provide a place to safely lift the main corer over the side of the ship, without causing it to bend or break. There is also a wire that runs up from the lifting collar to just under the corehead. During recovery, a hook from a crane is attached just below the corer. The angle provided by the wire during the recovery lifting, helps to lessen bending of the main corer, which could break the sediment core that had been collected.

Contact the TEA in the field at

.

If you cannot connect through your browser, copy the

TEA's e-mail address in the "To:" line of

your favorite e-mail package.

|