16 November, 1999

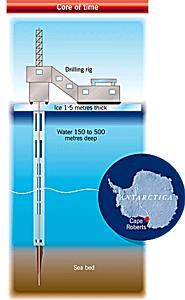

On to the drill site! The Cape Roberts Project drill site is located about

12 kilometers (a bit over 7 miles) away from CRP base camp out on the sea

ice of the Ross Sea. Work at the drill site began in October when all of the

equipment was dragged on to the ice on skids by bulldozers. The entire drill

rig and the base camp were stored on land during the winter before being put

into place on the ice. The route from the base camp to the drill site is not

a straight line. A safe path must be found by winding around icebergs frozen

in the sea ice, avoiding rough ice, and crossing at stable places in the

many cracks. The rig is located over about 300 meters of water and needs

about 2 meters (6 feet) of ice to support it. As one approached the rig from

the air, it looks like a smaller version of a traditional drill rig. It is

enclosed at the base with the derrick extending above the rig. The drill

pipe consists of a donut shaped bit on the end of a string of rotating pipe.

The bit has diamonds imbedded in it to allow the bit to chew away at the

rock. As the bit spins, it forces a shaft of rock into a metal sleeve inside

the drill pipe. At regular intervals, this "core" of rock is pulled out of

the pipe and a new sleeve is inserted. As the bit goes deeper into the rock,

more drill pipe is added at the drill rig. Occasionally the drill bit wears

out and needs to be replaced. A lot of things can go wrong in this process.

The drill rod can break, they can hit layer of very hard rock or there can

be other mechanical problems. So far, the CRP drilling has gone very well.

They have drilled over 840 meters into the sea floor. This is a record for

Antarctic drilling. Add to this the 300 meters of pipe to get to the bottom

of the sea and you have over a kilometer of drill pipe hanging from this rig

on the ice. To help support this tremendous amount of weight, there are

floatation devices and air bags attached to the drill pipe. In addition,

there are two large air bags under the ice directly under the rig to support

it's weight.

The drilling crews work 12-hour shifts. At the end of the shift they

are flown back to the base camp by helo (Unless there is bad weather, then

they have to go over the ice.). Drilling continues 24/7. During their 12

hours off, the crew eats, relaxes and gets some sleep. Then it's back to

work. The scientists at the drill site work the same schedule. The cores are

delivered from the rig to the geologists in the core processing building.

Here the core is analyzed, electronically imaged and cut in half. One half

of the core will be used to take samples from while the other is stored for

later study. The cores are then flown back to the base camp where they are

studied and described by geologists there. After this initial study, cores

are flown back to McMurdo where technicians, like me, and scientists can

process, analyze and study samples of the core material.

One of the ways they make sure the drilling goes smoothly is by

using a special camera that can see the entire drill string from just below

the ice all the way to the bottom of the sea. This camera system is located

in a small building next to the drill rig. The camera is lowered into the

water through a large hole cut in the ice. The drilling operation can be

monitored with this camera. In addition to the camera equipment, a large

seal has taken up residence in the hole. The people at the drill site have

named him Frank. While I was in the video shack watching the monitor, Frank

stuck his head out of the hole to get air. His breath smelled of fish! I got

a good picture of Frank.

At the end of our tour of the drill site, we headed back to the base

camp via a Hagglund, a two-piece, tracked vehicle. We got back in time for

lunch. I then had the opportunity to visit some really cool ice caves. I

will tell you about those tomorrow.

Today's featured CRP Team Members represent the drillers that work

at the drill site. They are Todd Symons from Townsville in Queensland,

Australia and Jeremy Ridgen from Greendale, New Zealand. Both Todd and

Jeremy will continue work at other drill sites around the world when the CRP

is done, as will most of the drill crew.

Special note to those of you doing the evaporation experiment. I continue to

have problems with the water eating holes in my aluminum plates. Are any of

you having this problem? I am going to have to start over with a new,

perhaps plastic, container. You keep going with your experiment if you have

started. We can still compare data when we are all done.

The Cape Roberts Project drill site. Those are the Transantarctic Mountains in the distance. (This picture was taken by Chris Buecker)

A diagram of the drill rig.

This is where the drill pipe is fed into the rig. It is then attached to the drill string in the hole.

This is in the core processing building. Shelli, a graduate student from Ohio State, is electronically imaging the core.

Here is a drilling crew loading on the helo during a shift change.

Frank the Weddell seal.

Todd Symons, left and Jeremy Ridgen.

Contact the TEA in the field at

.

If you cannot connect through your browser, copy the

TEA's e-mail address in the "To:" line of

your favorite e-mail package.

|