| |||||||||||||||||||

|

|

Journals 2008/2009Steve Howard

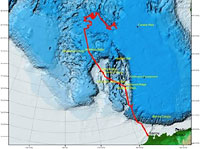

August 24, 2008 Before we get into today's journal, here's a quick update on our path: we have been carefully mapping the southeastern extent of our transect, and will now be heading back up north and east for a number of days, ultimately reaching our closest point to the North Pole. Then we will begin the long route back toward Barrow. The seafloor mapping continues to go relatively smoothly, although smashing through the ice often creates challenges to the system with "noise" in the data that must be carefully considered and selected out.

Today a few of us were treated to a very comprehensive tour of the ships "innards," by which I mean all the engineering spaces, storage, electrical systems, generators, and so forth. The tour was lead by Master Chief Electrician Curt Podhora. It didn't take long before I was completely lost, going up and down ladders and in and out of bulkhead doors as we worked our way through the maze of machinery and computerized and electrical systems that keep the Healy purring along. The scale and complexity of these systems boggles the mind, and I won't pretend to have grasped more than a fraction of all we saw on this tour. But, here are some of the basics... The Healy, which is the newest icebreaker in the Coast Guard fleet (commissioned in 2000), has four immense engines which are driven by four equally immense diesel driven generators. It burns about 400 to 500 gallons of diesel fuel per hour (not great mileage, but hey, your Prius isn't 420 feet long!) to drive the two sixteen foot diameter propellers, which can move the Healy at a maximum speed of 17 knots in open water. The system is constantly monitored by Coast Guard personnel, who keep an eye on the 5800 sensors distributed throughout the system which alert those on duty if anything is amiss. Because the Healy is a vessel which spends months at a time in remote areas, it must be completely self-sufficient, managing it's own sewage, making it's own drinking water (6,500 gallons per day) using saltwater distilling machines, recycling and incinerating its own trash, generating its own electricity, and so forth. Folks like Chief Podhora and the crew have to rely on expertise and resourcefulness to fix things that are broken and improvise solutions when parts are unavailable (you can't just call Napa out here in the Arctic). Traveling through the inner workings of the ship, you find pipes of all dimensions running everywhere. I have to admit, after a few hours I became pretty overwhelmed with both the scale and the complexity of these systems, and I kept thinking about how much time and experience would be required to understand how to manage it all. Whether you are at the bow watching the ship cut through six-foot ice or in your stateroom brushing your teeth, it's easy to forget all the machinery that is necessary to keep the ship moving or the water running. My great respect goes out to the men and women working tirelessly below our feet who make all this happen.

PROFILE:

|

||||||||||||||||||